Dr Brakes Complete Auto Repair - Coral Ridge Isles, FL

- brake repairs Palm Aire, FLReplacement brake hardware: Ensure Performance and safety

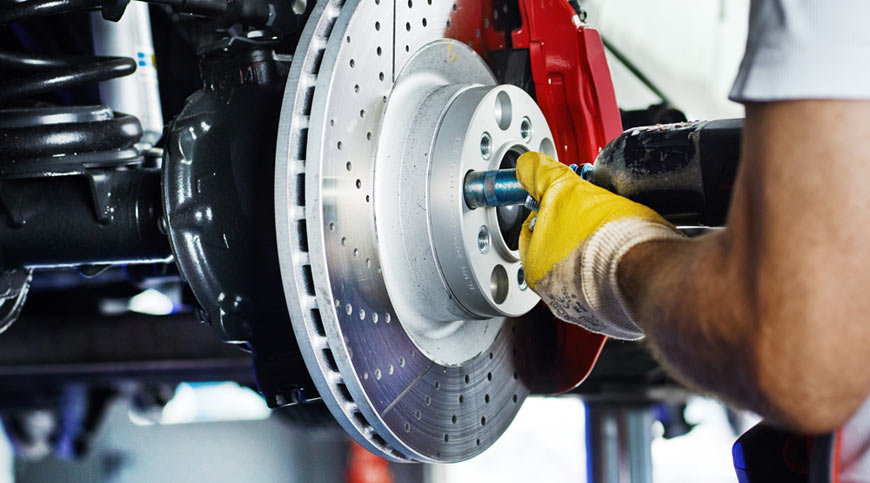

For both safety and performance on the road, keeping your car's braking system in good condition is essential. Replacement of the brake hardware is a crucial step in this maintenance procedure. In this thorough guide, we'll discuss the steps involved in replacing brake hardware, the significance of doing so, and the warning signs that it's time. This article will offer insightful information on brake hardware for both experienced mechanics and car owners who want to learn more about it.

Why Replacement of Brake Hardware Is Important

- Safety First: A vehicle's braking system is one of its most important safety features. Brake hardware can deteriorate over time, reducing braking effectiveness and creating potentially dangerous circumstances. Wear-out brake hardware replacement makes sure your car can stop quickly when needed, lowering the risk of accidents.

- Optimal Performance: Your brakes' smooth operation depends on the performance of your brake hardware, which includes parts like caliper pins, clips, and shims. When necessary, replacing these parts can improve the performance of your braking system and give you a more comfortable driving experience.

- Extended Brake Pad Life: Uneven wear on brake pads can be caused by worn or damaged brake hardware. You can increase the life of your brake pads and ultimately save money on replacement costs by replacing the hardware.

Signs that Brake Hardware Replacement Is Required

Car Performance Parts Parts Near Pompano Beach, FL

(brake system service Margate, FL)To keep your car's performance and safety intact, knowing when to replace the brake hardware is crucial. Watch out for these typical symptoms:

- When applying the brakes, you may hear high-pitched noises that indicate worn-out brake hardware. This is known as squeaking or silo-clasping. Friction between the hardware components frequently results in squeaking noises.

- Reduced Braking Performance: A noticeable decline in the braking performance of your car, such as longer stopping distances or a soft brake pedal, may indicate the need for new brakes.

- Wear Uneven Brake Pads: Regularly inspect your brake pads. If you notice that they are wearing unevenly, the uneven pressure distribution may be caused by faulty hardware.

- Vibration or Pulsation: Warped brake hardware or damaged components may cause vibrations or pulsations when applying the brakes.

- Visible Damage: The brake hardware can occasionally be visually inspected. Check for indications of physical damage, rust, or corrosion. Any damaged hardware needs to be replaced right away.

The process of replacing brake hardware

You can replace your brake hardware by using the following procedures:

- Gather the necessary Tools: You will require a socket set, pliers, and c-clamp, among other basic hand tools. Have brand-new brake hardware parts prepared for installation as well.

- First and foremost, make sure the parking brake is engaged and your car is parked on a level surface. Wear appropriate safety gear, such as gloves and safety glasses, and use wheel chocks to secure the vehicle.

- Remove the Wheel: Unlock the lug nuts on the wheel connected to the new brake hardware. Use a jack to lift the car, and then secure it with the helper stands. The wheel should then be completely taken off.

- The brake caliper and bracket are located in the brake hardware section. You might have to take the caliper off your car in order to access the hardware. For advice, consult the repair manual for your car.

- Replace Hardware Components: Get rid of any outdated hardware parts, such as shims, clips, and caliper pins. Make sure the mounting surfaces have been thoroughly cleaned. Replace the missing hardware components with new ones.

- Reassemble and Test: The brake caliper and bracket should be carefully reassembled, and all parts must be securely fastened. Bolts and pins should be tightened to the manufacturer's specifications. Check the brake pedal to make sure it feels firm before turning the wheel back on.

- Installing a wheel involves putting the wheel back on and manually tightening the lug nuts. Use a torque wrench to tighten the lug nuts to the suggested torque settings after lowering the car off the vehicle's jack stands.

- Brake Bedding: It's crucial to properly bed in the new parts after replacing the brake hardware. To ensure optimal performance, adhere to the bedding - in procedure outlined in your car's manual.

- Final Inspection: Double-check that every piece of hardware is firmly in place. While driving, keep an ear out for any strange noises to make sure the brake hardware replacement was successful.

Conclusion

Dr Brakes Complete Auto Repair: Auto Repair Coconut Creek, FL

Replacement of brake hardware is an important component of vehicle maintenance that shouldn't be disregarded. It guarantees both your road safety and the best possible performance of your braking system. You can keep your car's braking system in good working order by being aware of the telltale signs of worn-out hardware and carrying out the right replacement procedure (brake check North Andrews Gardens, FL).

Remember that it's always a good idea to seek the advice of an experienced mechanic if you're unsure about performing brake hardware replacement yourself. A well-maintained braking system is essential to maintaining your safety, which is of the utmost importance.

find more information Going Here More about the author